820 2121

"Our Focus your Finish"

820 2121

"Our Focus your Finish"

Blast Guns

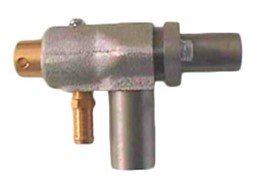

SYNTECH BLAST GUN

The Syntech model blast gun is a very efficient precision piece of equipment. The pressure and suction hose connections are located at the bottom to provide the operator freedom of use without becoming entangled with hose leads.

The main advantage with this particular blast gun is that it is very adaptable because the blast nozzles can be interchangeable from 1/4", 5/16", 1/2", 3/8". This gun will provide trouble free operation within the life of the Tungsten Carbide Nozzle.

It is recommended that the nozzle tip must protrude beyond the face of the gun body by 4mm to effect good blasting. Regular cleaning of the air nozzle and inner chamber of the gun body will prevent erosion of the aluminium casting by misdirected abrasive media. This can be done on changing nozzle sizing.

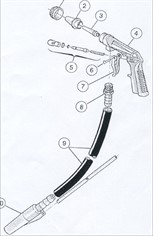

SYNTECH ANI A209 BLAST GUN

Syntech sells a complete range of guns for surface treatment for DIY, for industry, for professional use and for car repair shops. The above pictures show the Syntech A.N.I. Suction Blast gun model A-209 and version A209B with suction cup. The model A-209 comes with suction pipe.

Manufactured in Italy the A.N.I. Suction blast guns adapt perfectly to the surface to be sanded, resulting in safe, precise work without wasting abrasive.

Optional Extra

A Tungsten Carbide Nozzle can be fitted as an optional extra.

SYNTECH ANI A211 BLAST GUN

AN.I. poduces a complete range of guns for Surface Treatment for DIY,

industry, for the professional user and car repair shops.

The picture shows the ANI-A211 Blast gun model

Complete with suction cup and cloth spent abrasive bag.

Manufactured in Italy the ANI Suction blast gun adapt perfectly to the surface to be sanded, resulting in safe, precise work without wasting abrasive media.

The cloth bag allows the operator the ability to reclaim some of the media from the blasting action.